Laser Metal Deposition

Forging a real lightsaber wasn’t an option—so I mastered lasers in metal deposition instead 💥

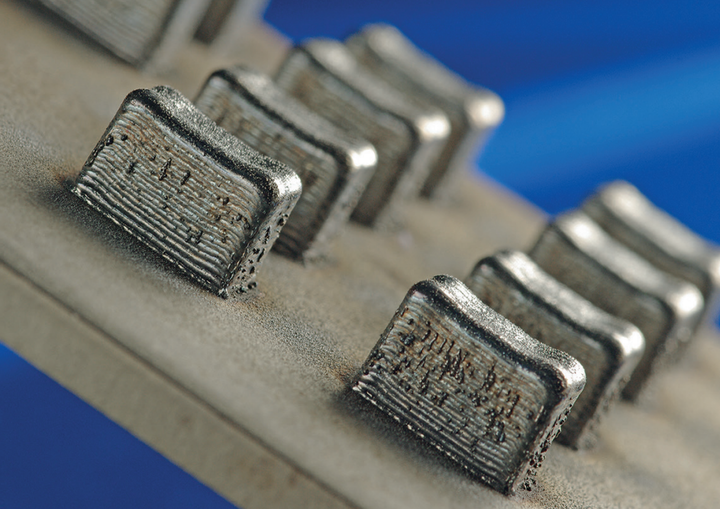

FeAL test specimen produced with Laser Metal Deposition. Image credit: Fraunhofer ILT 2015 Report

FeAL test specimen produced with Laser Metal Deposition. Image credit: Fraunhofer ILT 2015 ReportAs an undergraduate research assistant at the renowned Fraunhofer Institute for Laser Technology ILT at RWTH Aachen University, I independently conducted additive manufacturing experiments that studied the feasibility of producing low-porosity iron-aluminide alloys with Laser Metal Deposition (LMD). My work specifically focused on the in-situ grading of Fe-28at.-%Al with either pure aluminum or stainless steel (1.4404). These alloys are of growing interest for high-temperature and corrosive environments due to their lightweight nature and oxidation resistance, making them suitable for applications such as turbine blades.

I independently designed and conducted experiments, optimizing powder feed rates to achieve a stepwise increase in aluminum content and managing the transition from stainless steel to iron-aluminide in hybrid structures. To improve process efficiency, I adjusted laser parameters and preheating conditions, achieving material densities exceeding 99.5% with LMD. Additionally, I programmed laser trajectories using G-Code for precise material deposition and modified and repaired the laser metal deposition nozzle to maintain a stable and consistent flow rate.

Beyond my technical contributions, I was also solely responsible for all safety precautions in this high-risk environment, working independently in a 5x5-meters enclosure with a high-powered laser. This included ensuring proper respiratory and eye protection and adhering to strict laser safety protocols to mitigate hazards.