Electrohydrodynamic Jet Printing

Reducing electrostatic noise - or how to chase tiny charges with tinfoil ⚡

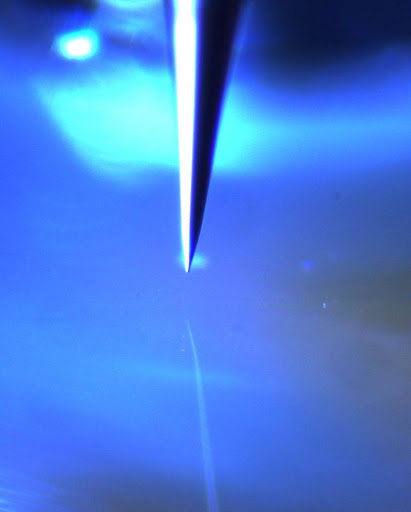

Nozzle with 10 µm opening used for E-jet printing

Nozzle with 10 µm opening used for E-jet printingAs an Undergraduate Research Scholar at the University of Michigan, I had the opportunity to work on Electrohydrodynamic Jet (E-jet) Printing in the Barton Research Group. This high-resolution printing technique utilizes an electric field to manipulate a polarizable liquid, allowing for precision droplet deposition at the nanoscale.

E-jet printing operates by applying an electric field to a conductive liquid, causing mobile ions to accumulate at the liquid surface. The Coulombic repulsion deforms the liquid meniscus into a Taylor cone, and when the electric field exceeds a critical limit, a fine droplet is emitted towards the grounded substrate. This technique enables droplet sizes as small as 240 nm with exceptional spatial accuracy in the hundreds of nanometers, making it highly suitable for microfabrication and printed electronics applications.

Addressing Noise Issues in E-Jet Printing

One of the primary challenges in achieving high-resolution printing is mitigating noise disturbances in the measured current, which affected our ability to detect the charge of each emitted droplet. Detecting these charges was crucial for creating feedback control loops and advanced control loops such as iterative learning control. Noise sources in the system can be categorized as intrinsic (amplifier noise, connection inconsistencies) and extrinsic (power supply fluctuations, electromagnetic interference). My research focused on diagnosing these noise sources and implementing effective reduction strategies.

Key Contributions & Methods

- Noise Source Identification

Conducted in-depth analysis of conductive, capacitive, inductive, and radiative noise coupling.

Studied the impact of ground loops and system setup inconsistencies on print accuracy.

- Shielding and Circuit Optimization

Improved system grounding and shielding techniques to minimize capacitive and radiative noise.

Experimented with different amplifier configurations to optimize signal integrity.

Extensive covering of electronic equipment with tinfoil for electromagnetic shielding.

- Hardware Modifications for Enhanced Performance

Optimized experimental setup by using shorter cables, high-quality soldered connections, and isolated substrate mounting.

Implemented differential signaling to reduce interference in signal transmission.

Results and Future Outlook

We successfully reduced noise levels in the measured current, enabling the detection of droplet charges with high precision. Every time a drop was emitted and hit the substrate surface, the charge of the droplet caused a sudden spike in the measured current. This spike served as an indicator of droplet ejection, allowing for real-time monitoring and feedback.

References

[1] Barton, K., Mishra, S., Alleyne, A., Ferreira, P., Rogers, J. (2011) Control of high-resolution electrohydrodynamic jet printing. IEEE Transactions on Control Systems Technology 19(6):1481-1493.